Tin Bronze, Silicon Bronze, and Brass are all copper-based alloys with various applications.

Stainless steel welding requires a specific set of tools and techniques to ensure a strong and reliable weld. In this Blog, we will discuss the key components of stainless steel welding and the different types of welding wires and electrodes available.

As a Chinese foreign trade company specializing in brazing alloys, BeiduoAlloys is committed to providing high-quality brazing materials and professional brazing solutions to our customers.

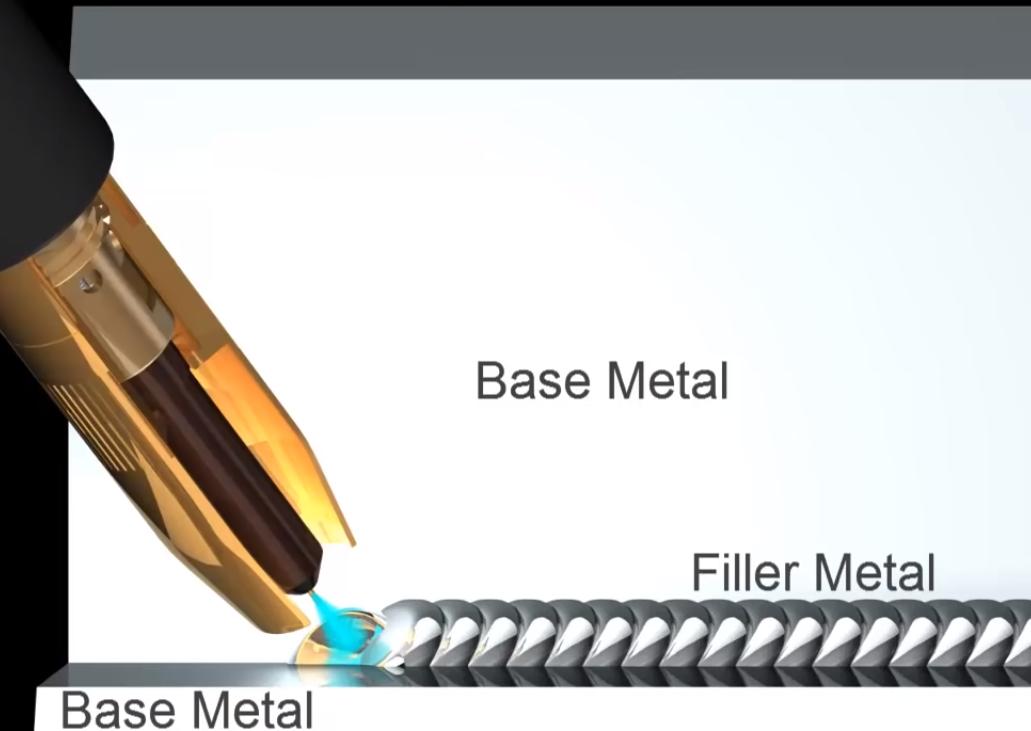

Braze joining is used to join two metal pieces or parts without affecting the internal structure of metal pieces to be joined. Internal structure and thus properties of a metal parts are affected by heat.

The four main types of welding are: Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), Shielded Metal Arc Welding (SMAW), and Flux Cored Arc Welding (FCAW)

Copper and phosphorus are the two major elements in the copper-phosphorus brazing alloys. The alloys have good fluidity, low melting temperature and the trait of self-fluxing.

Silver brazing alloys, suitable to join easily a wide range of ferrous and non-ferrous base materials (iron, steel, stainless steel, copper, brass, etc.)

Oxygen-free copper (OFC) or oxygen-free high thermal conductivity (OFHC) copper is a group of wrought high-conductivity copper alloys that have been electrolytic refined to reduce the level of oxygen to 0.001% or below.

Brass Brazing Rod is balanced zinc and copper alloy.Features excellent ductility and is smooth flowing.Excellent for brazing sheet metal pipes,fenders,water tanks and many cast iron applications.Requires flux.

Select filler metal for a brazed joint depends on five main points: properties of the filler metal,joint design,service requirements,base metal composition,cost and availability.

High Temperature Brazing uses vacuum or protective atmosphere furnaces to join complex assemblies made in stainless steels or other high alloy base materials. The technology is used for the drill, oil exploitation industry, used for the manufacture of hea

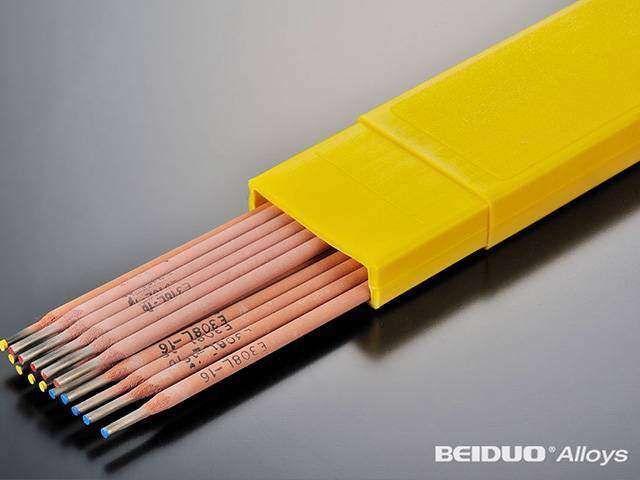

A filler metal is a metal added in the making of a joint through welding, brazing, or soldering. Four types of filler metals exist—covered electrodes, bare electrode wire or rod, tubular electrode wire, and welding fluxes.

Hi-temp alloy CuMn23Ni9.5,Because of its High-strength, it’s widely used for cutting #picks .

utomatic ring segregating machine BDTH-3 with eight-rail can replace the manual segregating with high efficiency.

Phosphorus copper brazing strips applies to automatic brazing Silver contacts or Traverses in Switches; Stator in motors, sunglasses flame,etc.

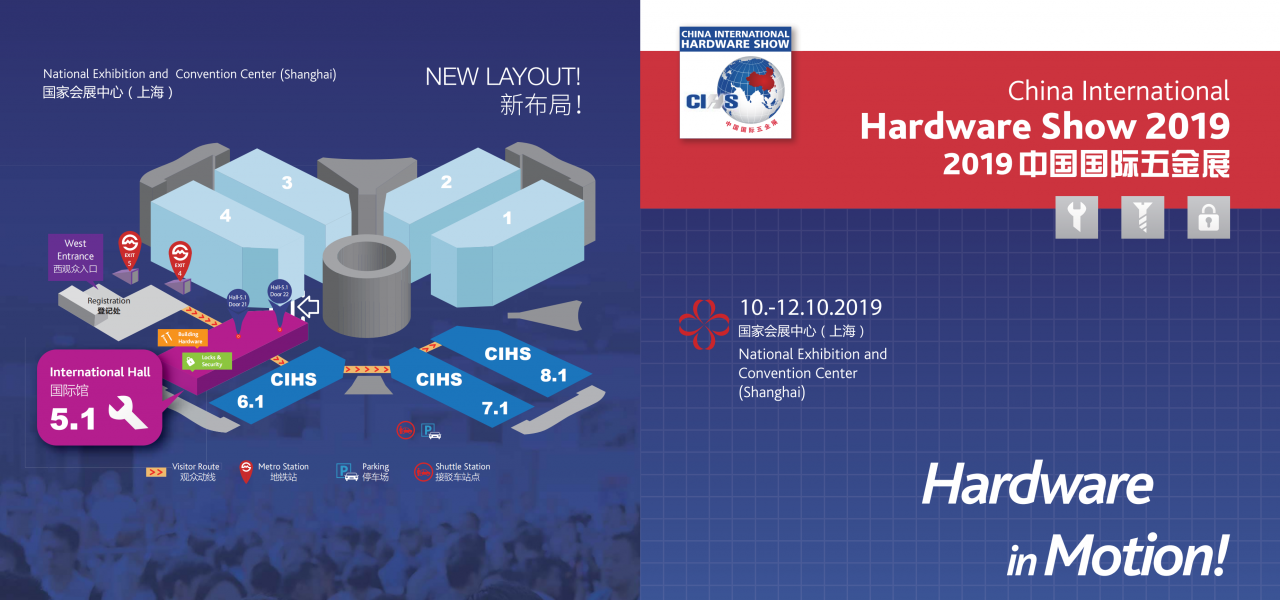

Beiduo Alloys will attend China International Hareware Show 2019 in Shanghai from October 10th to 12rd.

Cu52.5Mn38Ni9.5(CuMn38Ni9.5) is a copper based, high temperature brazing alloy. It is suitable to join steels, stainless steels, nickel alloys and cemented carbides.

We will exhibit at the Essen Beijing Welding & Cutting Exhibition from 27th to 30th, June 2017

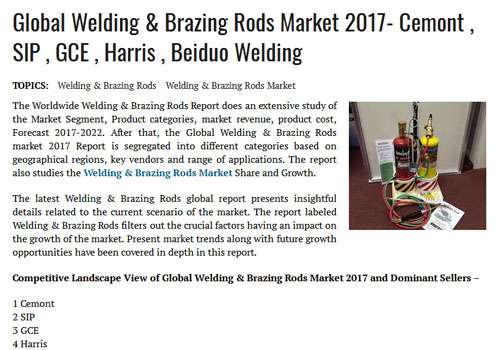

Beiduo is honor to list one of Top5 Competitive Global Welding & Brazing Rod Market and Dominant Sellers.

BEIDUO will attend Intermach exhibition from 17 to 20 May., 2017 in Thailand.

BEIDUO Alloys attend Canton fair from 15th to 18th April, 2015.

This year, BEIDUO Alloys will attend Fabtech in Chicago, USA .

#Desoldering braid, also known as desoldering wick or solder wick, is widely used to remove solder from printed circuit boards, solder joints, or other #electrical components.

This year, BEIDUO Alloys will attend Fabtech in Chicago, USA .

BEIDUO will attend ACREX from 23rd to 25th, February, 2017 in India!