The aluminum bronzes are a family of copper-based alloys offering a combination of mechanical and chemical properties unmatched by any other alloy series.Used for welding aluminum bronze plate fabrications and for joining dissimilar metals such as cast iron, carbon steels, copper, bronze and copper-nickel materials. Applications include wear surface reconstruction, casting repair and general maintenance, and galvanized sheet metal fabrication when high strength welds are required.

Silicon bronze filler metal is a copper-base alloy containing approximately 3% silicon. It is used for gas tungsten and gas metal arc welding of copper-silicon and copper-zinc alloys (brass) and for welding steel to itself or to these alloys.

Tin Bronze (Phosphorus Bronze) filler metal is a copper-tin alloy. It is used to weld bronze, brass and copper. Phosphor Bronze A is frequently used to repair castings and join copper-tin alloys of similar chemical composition.

ERCuNi (NA67) is used for gas metal and gas tungsten arc welding. Can also be used by oxy-fuel welding of 70/30,80/20, and 90/10 copper nickel alloys. A barrier layer of nickel alloy 610 is recommended prior to overlaying steel with GMAW weld process. Note: Other shielding Gases may be used for Tig welding. They are the materials of first choice for seawater pipework and condenser/heat exchanger service

ER Cu filler metal is deoxidized copper with small quantities of phosphorus, silicon, tin, manganese and silver. The phosphorus and silicon are primarily deoxidizers, and silicon and other elements improve fluidity and ease of welding. This metal is normally used to weld deoxidized copper (C12000 and C12200) and electrolytic tough pitch copper (C11000). Preheating is desirable for most work, but it is essential for heavier gauge welding. Preheating temperatures of 400°F to 1OOO°F (205°C to 540°C) are suitable.

Aluminum mig and tig Aluminum Alloy Welding Wire in different alloys and a variety of package sizes. Specialty items as well as the industry standards are available.

Stainless steel welding wire is shielded Arc welding wire ,belong to solid wire , The wire has a very good performance and has a large range of current in welding.Suitable for the welding of dissimilar metals such as mild steel to stainless steel.

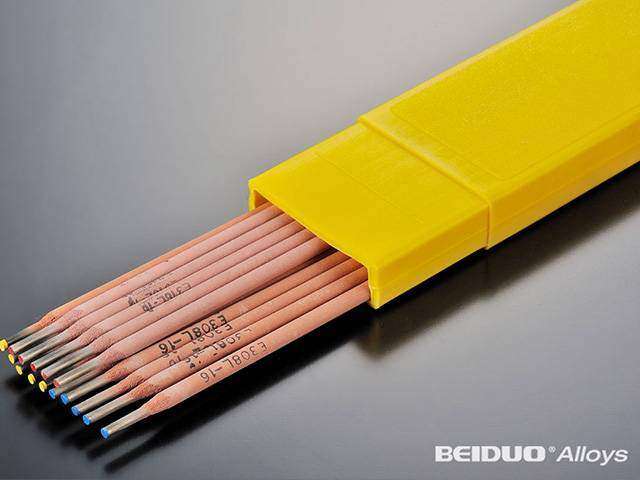

Welding electrodes are metal wires with baked on chemical coatings. The rod is used to sustain the welding arc and to provide the filler metal required for the joint to be welded. The coating protects the metal from damage, stabilizes the arc, and improves the weld

These Nickel-base alloys are generally used when specifications require good corrosion resistance and/or extreme service temperature (both high and subzero) properties. Ideal for brazing of stainless steels and nickel based alloys.

Tungsten Inert Gas welding(TIG) or Gas Tungsten Arc welding(GTA W) uses a nonconsumable tungsten electrode which must be shielded with an inert gas,The arc is initiated between the tip of the electrode and work to melt the metal being welded,as well as the filler metal,when used. A gas shield protects the electrode and the molten weld pool,and provides the required arc characteristics.

AZ61 is a magnesium alloy contains 6%Al and 1%Zn. It has advantages ranges over good anti-corrosiveness.